Seaweld Engineering Ltd, fully owned and managed by Ghanaians with local workers drawn from the country’s technical institutions, is fabricating deckstools, components used for laying decks (floors) in ships.

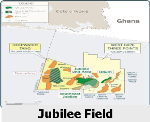

The Singaporean company, MODEC, which built and manages FPSO Kwame Nkrumah, has the contract to build a second FPSO for the Tano, Enyiara and Ntummy (TEN) oil field which is due to produce oil by the close of the year.

Seaweld, a sub-contractor, will complete the stools and ship them back to Singapore for the assembling of the FPSO for the TEN deepwater wells. The first shipment is due at the end of this month, with two others expected by the close of May this year.

The role of the local contractor gives meaning and manifestation of the country’s Local Content and Participation in Petroleum Activities Regulation, 2013 (L.I.2204), passed November last year, which aims are courting oil companies in the country to use local resources, human and material, in their activities.

“What Seaweld is doing here is to complement the job of the manufacturers, MODEC. This is because of the trust they have in the company and the skills they have seen over here,” the Operations Manager of Seaweld, Mr Ralph Afodoanyi, said.

While manufacturing the pieces of the vessel, MODEC also has its engineers onsite to ensure that Seaweld delivers to specification and standard.

Fafali Adagbedu

The Chief Executive Officer of Seaweld Engineering, Mr Alfred Fafali Adagbedu, said the focus of the company was to produce to global standards and showcase the expertise from Ghana and its talents on the international platform.

The project means that Seaweld has to handle about 450 tonnes of steel – approximately the size of 22 long articulated trucks – at its workshop in Takoradi. But the chief executive is not perturbed, as he sounded emphatic; “I can tell you it will be delivered on time.”

Mr Adagbedu said the Seaweld team was happy to have won part of the contract for the fabrication of some of the vital components for the construction of the second country’s Floating Production Storage and Offloading vessel.

Quality of work

The Ghanaian company is ISO 9000 certified and retrains its workers after their NVTI certification. It also shepherds the artisans to sit for internationally recognised examinations.

The company also boasts of the full range of industrial welding machines that match its kind in any part of the world. The great complement of equipment laced brings the professionalism and dexterity of its workers and enables Seaweld to churn out quality and well-finished products that match any of their kind anywhere.

Besides the skillful artisans, Seaweld also engages the services of qualified engineers. They include project engineer, welding manager and welding supervisor, who combine forces, expertise and finesse to ensure that jobs are delivered to specification, standard and on time.

The company

Seaweld is an offshore engineering company involved in fabrication. It renders services such as scaffolders, cleaning on the rigs and other ancillary services ranging from car rentals to hospitality facilities such as accommodation.

Having worked with a similar company in the United Kingdom, the promoters of the company saw the need to meet expectations in Ghana’s nascent oil and gas industry and positioned itself to become an industry giant and major player by acting as a one-stop shop for the oil and gas industry.

A Seaweld Project Engineer, Mr. Dennis Adrah, told the GRAPHIC BUSINSS team which visited the company’s head office in Takoradi that the company had made itself so indispensable in the offshore oil and gas industry.

The company has been around right from the discovery of oil in commercial quantities until now.

Commitment to international standards and the need to create a one-stop shop for solutions to the needs of the oil and gas industry has resulted in the company’s strong presence in Ghana and other West African countries.

In Benin, Seaweld is involved in the installation of a farm camp to support a rice project. The camp includes accommodation and offices.

Employment and social responsibility

The company, currently has a total of 166 workers, comprising 60 technical persons, 10 administrative staff and 102 contract staff.

Besides offering employment to many people in the Western Region, Seaweld is also having impact on the community through various corporate social responsibilities, including educational scholarships, and the construction of an ultra-modern care centre at the Efia Nkwanta Hospital to support mental health.

Financial support

Like many local companies operating in the oil and gas industry, Seaweld had the bank’s shying away from advancing loans to it, until recently when they troop to it.

While it now finds it easy to access credit, Mr Adagbedu said the challenge had been the high cost of credit which the banks offered.

“We can say that, Seaweld looks so attractive to banks now. However, their products are so expensive for us to contract,” he stated.

Tullow Oil and Jubilee Partners

The General Manager of Tullow, Charles Darku, and the Chief Executive of the Ghana National Petroleum Corporation (GNPC), Mr Alex Mould, have taken turns to commend the company for its sterling performance and contributions to the oil and gas industry.

Mr Darko was happy that a Ghanaian company had made it to the history books by winning a contract to be part of the construction of second FPSO.

“The success of Seaweld Engineering does not only show Tullow’s commitment to local content but aside the decision to construct part of the FPSO in Ghana, a Ghanaian company made it to the list of contractors,” Mr Darko said.

The chief executive officer of GNPC, during the tour of the facility, was optimistic about the fast pace of construction works on the deckstools by the Ghanaian company and described Seaweld as an example of the country’s success story in oil and gas operations.

A Ghanaian engineering company which provides support services for the oil and gas industry has put the country on the international map for being the only indigenous company to build part of the second Floating, Production, Storage and Offloading (FPSO) vessel.

A Ghanaian engineering company which provides support services for the oil and gas industry has put the country on the international map for being the only indigenous company to build part of the second Floating, Production, Storage and Offloading (FPSO) vessel.